R&D

R&D

In 1980, we spun off our R&D division and established Dai-ichi Seiko Laboratories, Inc. (now Enplas Laboratories, Inc.) to pursue innovative product development that goes beyond merely improving existing products.

Enplas Laboratories focuses on three areas of activity: applied technology development, elemental technology development and analysis. It also conducts various R&D projects from a backcasting approach that starts with, for example, the goals of the SDGs or the type of world enabled by AI and autonomous driving technologies.

R&D organization

In the Enplas Group, research and development are carried out by Enplas Laboratories and the development group of each business unit, spanning some 60 employees. We work with universities and private companies, many in Japan, in the application of cutting-edge technologies and also pursue commercial application through start-ups and other ventures in the US and UK. We also perform data analysis to optimize the shape of products—one of our strong suits.

ESG in R&D

In our Life Science Business, we are developing microfluidic chips to be used in genetic testing equipment as well as a range of resin products for the life sciences field.

In our Semiconductor Business, we are developing semiconductor test sockets for electric vehicles/autonomous driving that will lead to reduced environmental impact, and also test sockets for servers that will contribute to the realization of an affluent society.

In our Network Solution company, we are developing high-precision lens products in anticipation of next-generation mobile communications systems in the optical communications field.

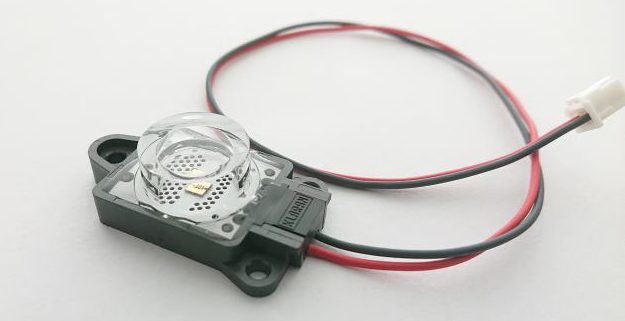

Enplas Laboratories is working to develop new plastic materials and processing technologies with the aim of using biomass plastic materials and biodegradable plastic materials to reduce the environmental footprint of engineering plastics. They also developed a viral sterilization device that can be used on masks and other medical personal protective equipment by applying water sterilization technology that uses UVC-LED (short-wavelength ultraviolet light).

Examples of initiatives

Asahi Kasei chooses Enplas UVC optical devices for use in its UVC LED units

Asahi Kasei Corporation has chosen Enplas ultraviolet C (UVC) optical devices for use in its UVC LED units. Due to its ability to generate UVC light (200-280 nm) with outstanding disinfection (inactivation) performance, UVC LED lighting is a promising potential replacement for mercury lamps and expansion in its use is anticipated. By effectively radiating UVC light, our technologies can contribute to customer applications development by improving disinfection performance and reducing the numbers of UVC LED lamps used, resulting in cost optimization and energy conservation.

In addition to these UVC optical devices, we’re also developing various new applications, including water disinfecting modules that realize efficient disinfection of viruses and fungi. Drawing on our UVC LED light control technologies, we will continue to contribute to societal progress by delivering solutions for a wide range of social challenges, including COVID-19.

- Sustainability

- Sustainability at Enplas

- TCFD

- Environment

- Environmental Policy

- Environment

- Social

- R&D

- Compliance

- Human Capital

- Supply Chain