Energy Saving Solution

Cutting Edge Core Technology

Creating new value in every market and sector.

Making full use of cutting edge technology in every market and sector, continuing to provide solid technology and new value for the customer.

Development support to guide the customer’s optimal solution.

To become an essential solution supplier for customers, we participate from early stages of development, allowing us to make proposals aimed at realizing optimum specifications.

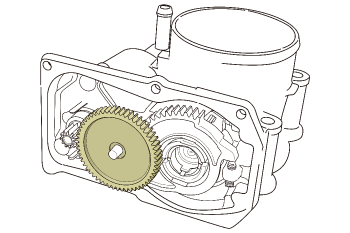

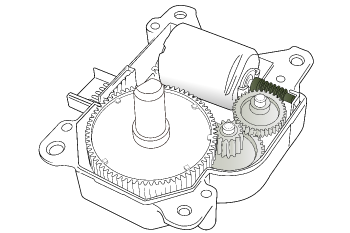

High-performance gears developed from solutions proposals

Based on customer feedback we develop high-performance gears that reduce equipment noise, enhance durability, and allow for more precise applications.

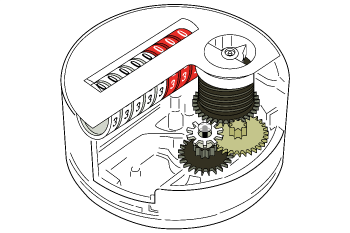

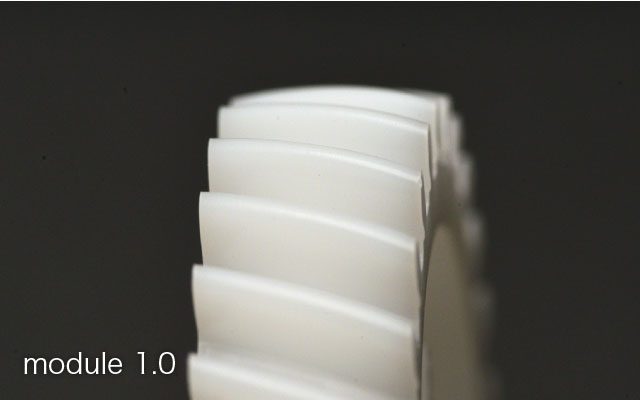

Double helical gear

With excellent noise reduction and durability, this multi-solution gear achieves high-precision transmission efficiency.

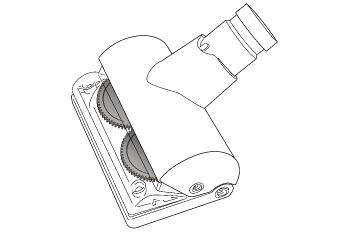

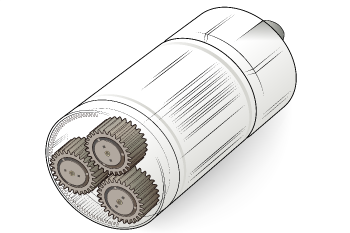

Crowning gear

A multi-solution gear for superior noise reduction and high revolution pitch transmission accuracy.

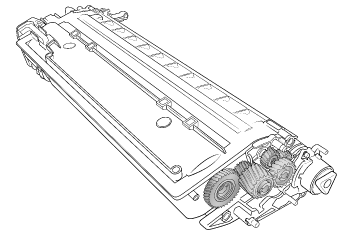

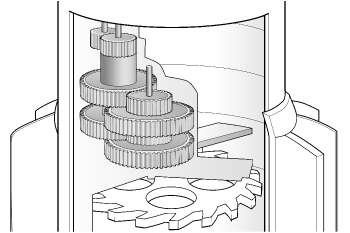

Face gear

Used in geartrains with orthogonal axis layouts, such as those in automobiles and printers. It is better suited for power transmission efficiency than a worm and wheel layout.

High precision gear

Expansion to fluid control

For the first time in the world, Enplas began mass production of a resin impeller for a turbo charger. The complex shape considered impossible with resin molding was successfully commercialized with its own original mold design and manufacturing technology.

Turbo impeller

Plastic impeller released in 1994 for adoption in turbo charger equipped vehicles. Enplas, by participating from the beginning of development, has succeeded in mass producing the complex shape that was considered impossible to accomplish with resin molding.

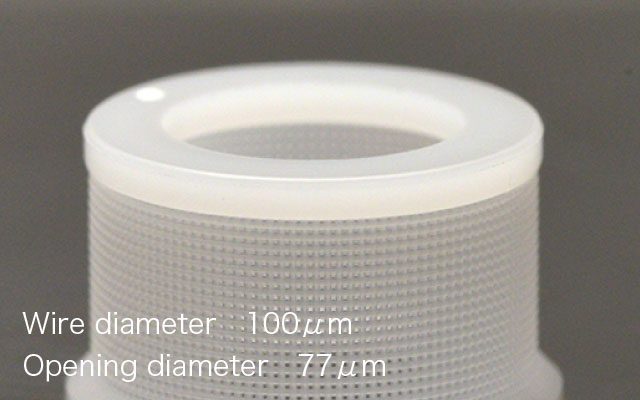

Mesh filter

Realization of an integrally molded mesh filter for fluid filtration. Based on state of the art technology, we pursue all the possibilities and function of what can be expected from a filter.

Wesco pump

Impeller for Wesco pump. Enplas implemented its advanced processing technology and succeeded in mass production of a wing shaped impeller that efficiently sends pressurized gasoline from the pump to the engine.

Consistent quality worldwide is the wellspring of customer trust and peace of mind.

We achieve consistent delivery of high-quality products by anticipating mass-production quality from the product development stage and by practicing a thorough process of proposals and engineering validation for product manufacturing from the mold design stage. For automotive products, Kanuma Plant and six factories in five countries outside Japan have acquired IATF 16949 certification and have built a quality assurance system based on a robust quality management system.

Mechanical Solutions

![]() Please click on the mark

Please click on the mark

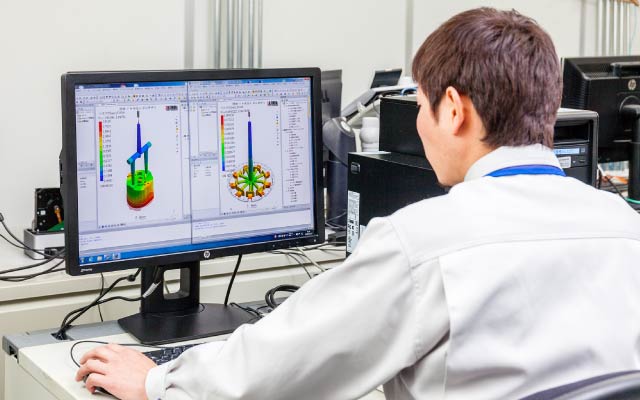

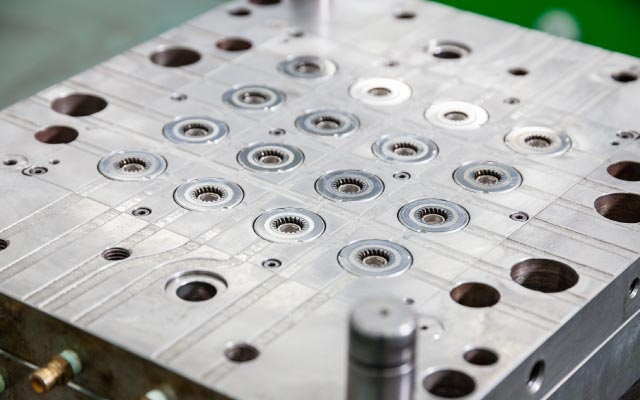

Molding-the base of Enplas’s craft since its founding

Mold design and manufacturing has consistently been an area of emphasis for Enplas since its inception. The thermal environment of the mold manufacturing sites is managed at constant conditions year-round. With technical capabilities backed by years of know-how, by making full use of the latest machining and simulation technology, we achieve higher precision, along with superior high performance and high durability.