Technology

State-of-the-art technology that opens up uncharted territory.

Enplas—always at the center of innovation.

With cutting edge technology and technical know-how backed by a long track record of experience,

from product development stages all the way to mass production management, Enplas provides total coordination.

Among the innovations that are evolving every day, we possess a spirit of challenge

that propels us to provide innovations to the world that can only be done by Enplas.

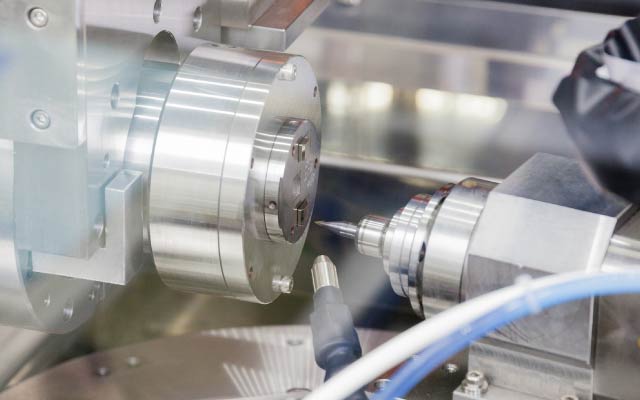

Precision molding technology

Moving into the realm of the nanometer

As a result of reducing the effects of temperature, humidity and vibration, we have succeeded in further improving the accuracy of Enplas’s precision mold processing technology.

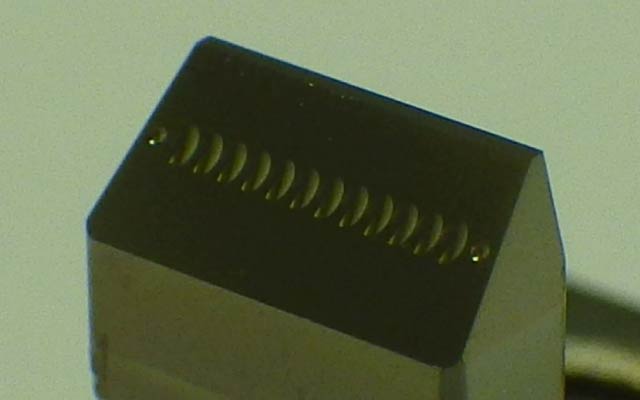

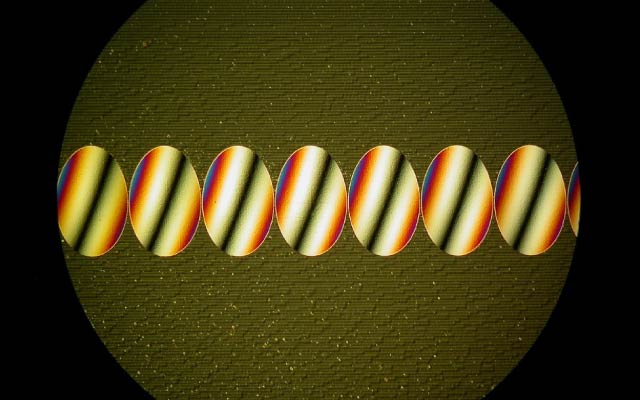

SR mark processed on both sides of an optical slope of 45 ° with 12 free-form surface lens array.

Using special tools, slope angle shaper accuracy, free-form surface array and SR surface (raster) pitch accuracy, nano-level accuracy has been achieved on the lens surface.

Free-form surface lens specification

Free-form surface lens specification

H: 0.38mm, W: 0.25mm, SAG (depth): 8.5μm

Lens spacing: 0.25mm

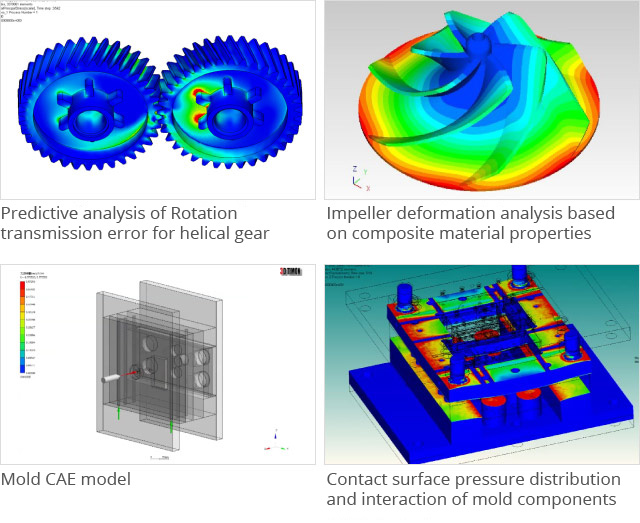

Analysis Technique

Evolving simulation technology

CAE (Computer Aided Engineering) has become common as a design technology. It is one of the key technologies that support innovation. At Enplas, from its inception we have been leveraging non-liner CAE for product/ mold design and development. Recently, we have started utilizing high performance computing technology (HPC). Together with evolving computer technology we continue to evolve our design and development technology.

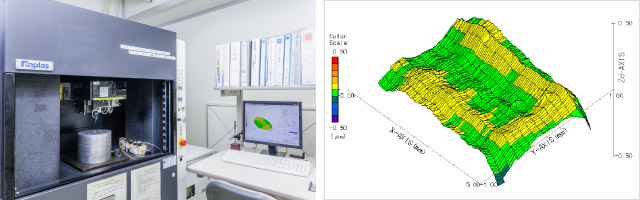

Precision measurement technology

Excellent evaluation technology

The strength of excellent precision measurement technology as a device manufacturer, accurate assessment of our products (shape, size, function) is required. Fully grasping and guaranteeing product specifications promised to customers (shape, size, function), we are committed to the improvement of our evaluation technology, introducing new evaluation equipment in order to respond to higher precision and diversification of product functionality.

Global quality assurance system

Enplas Corporation

[The Scope of the Registration]

1. Design, development, production and production management of precision plastic gears, plastic carburetor floats, optical elements and other injection molded engineering plastic precision products

2. Design, development and production management of IC Sockets and Carriers

Declaring same quality policy globally

To manufacture and supply products that satisfy customers, all Enplas entities worldwide have adopted a uniform quality policy and quality management system based on ISO9001. For automotive products, Kanuma Plant and six factories in five countries outside Japan have acquired IATF 16949 certification and have built a quality assurance system based on a robust quality management system.