Environment

Environmental policy and management

Our Environmental Policy states: “We view conservation of the global environment as an important corporate responsibility and we commit to working proactively to protect the environment in all areas of development, manufacture, and sales of high-precision, high-performance plastic precision parts and products.” Six of our business sites (see table) which have an environmental management system carry out these activities based on an environment manual.

The Environmental Committee, which reports directly to the president, discusses environmental issues of the Enplas Group. Subcommittees at respective business sites advance projects connected to these issues. Matters that require decision-making on a Group level are submitted for approval to the Corporate Strategy Meeting.

Environmental targets

We set annual environmental targets for each subcommittee of the Environmental Committee, conduct progress checks, and aggregate environmental impact data.

Environmental considerations in manufacturing Processes

Because we manufacture parts made of engineering plastics, energy use in injection molding and engineering plastic materials are important environmental aspects of our business. For this reason, we are focused on saving energy in manufacturing processes and in using engineering plastic resources efficiently.

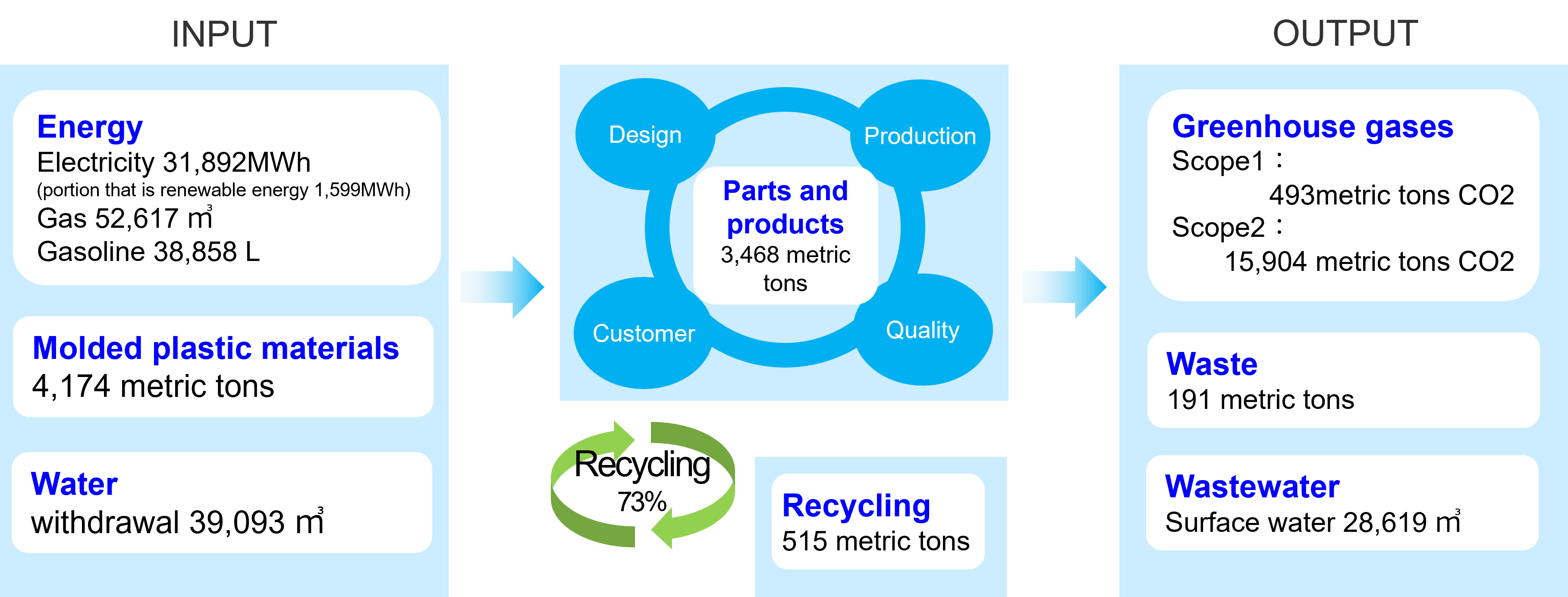

■Input and output flows (Global total)

For data on the Enplas Group’s ESG performance (from fiscal 2021 onward), please see the ESG Data.

Energy

The conversion of production equipment from hydraulic to electric systems has resulted in reductions in energy use in manufacturing processes.

In terms of energy use, we keep track of electricity and gas use. We also keep track of liquefied petroleum and natural gas use to identify our direct greenhouse gas emissions (Scope 1). For indirect greenhouse gas emissions (Scope 2), we keep track of emissions from electricity use. To prevent the leakage of hydrofluorocarbons (HFCs), we conduct periodic inspections of HVAC equipment.

■Energy use inside organizational boundary (portion that is renewable energy)

(Global total)

FY2024: Electricity in Global 31,892 Mwh(portion that is renewable energy *Including Enplas group companies in Japan: 1,599Mwh)

FY2024: Gas in Global 52,617 m3

FY2024: Gasoline in Global 38,858 L

■Energy use outside organizational boundary (portion that is renewable energy)

FY2024: Not accounted for

■Energy reduced through energy efficiency

FY2024: Not accounted for

■Total direct (Scope 1) GHG emissions (converted to CO2e)

FY2024: (Scope 1) GHG emissions in Global 492.65 t-CO2

■Total indirect (Scope 2) GHG emissions (converted to CO2e)

FY2024: (Scope 2) GHG emissions in Global 15,903.53 t-CO2

■Total other indirect (Scope 3) GHG emissions (converted to CO2e)

FY2024: Not accounted for

■GHG intensity of the organization

FY2024: Not accounted for

■GHG emissions reduced as direct result of emissions reduction efforts (converted to CO2e)

FY2024: Not accounted for

■Production, import and export of ozone depleting substances (ODS) (converted to CFC-11 (trichlorofluoromethane))

FY2024: Not accounted for

■Nitrogen oxides (NOx), sulfur oxides (SOx) and other significant atmospheric emissions

FY2024: Not accounted for

■Other

FY2024: Not accounted for

■Kanuma Plant

Kanuma Plant uses high-efficiency HVAC systems. It is also converting lighting used in manufacturing facilities, offices, and conference rooms to LEDs.

And in February 2024, Enplas installed 3,270 solar cells on the roof and parking space of Kanuma Plant. The solar cells reduced 20% of electricity consumption at Kanuma Plant. We strive to take actions proactively to achieve our CO2 emissions reduction goal.

Water

None of our manufacturing sites in Japan are located in areas with high water stress. We use clean water to wash and cool molds in the manufacturing process, but this amount is equivalent to that used residentially and commercially in toilets, etc.

■Kanuma Plant

Water used for washing molds and other manufacturing processes is released as wastewater after first treating it using pH neutralization systems to meet legal standards.

■Wastewater standards

We comply with Japan’s Water Pollution Prevention Act and the laws and regulations of each country.

■Breakdown of total water withdrawal : Fresh and other water types for each source (surface, ground, ocean, produced, third-party)

Fresh water (no other type of water is discharged)

FY2024: Withdrawal in Global 39,093 m3

■Breakdown of total water discharge Fresh and other water types for each discharge location (surface, ground, ocean, produced, third-party)

Fresh water (no other type of water is discharged)

Fiscal Year 2024: Surface water in Global 28,619 m3

Waste

To use resources efficiently, we make products using the hot runner method (which reduces waste in injection molding by heating plastic in the runners) and by reusing plastic materials in manufacturing processes.

We also recycle waste plastic and metal, selecting recycling companies appropriate for each business site. For toxic waste, we outsource processing to appropriate third-party businesses after first determining the volume and processing method.

■To reduce waste, Kanuma Plant has introduced reusable containers for parts and product transport, and also uses product trays multiple times.

■Plastic material usage at respective production sites

FY2024: Molded plastic material usage: 4,174 tons (global)

■Plastic recycled and recycling rate by production site

FY2024: Recycled 515tric tons (global)

*The amount of plastic material recycled is relatively low because most is shipped out as final products.

Recycling rate in FY2024 73%

*Ratio calculated based on mass of plastic recycled and wasted (Recycling rate = Plastic recycled/(Plastic recycled + Plastic wasted))

■Percentage of recycled materials used

FY2024: 0%

■Percentage of products reused

FY2024: 0%

Environmental education

We conduct environmental education at each manufacturing site. At Kanuma Plant, environmental education is focused especially on new employees. We also conduct environmental education, including tests, for all employees in Japan.

Environmental audit

We conduct periodic environmental audits.

■Points for consideration

FY2024 :1(already supported)

Legal and regulatory violations

In Japan, there were no regulatory violations resulting from the leakage of HFCs, oil, waste, or chemicals in FY2024 .

- Sustainability

- Sustainability at Enplas

- TCFD

- Environment

- Environmental Policy

- Environment

- Social

- R&D

- Compliance

- Human Capital

- Supply Chain